Equipment characteristics of copper/aluminum continuous extrusion machine

The production line are used to produce copper flat wire, copper busbar, commutator, contact wires for electric locomotive or other solid copper material. The finished products are widely used for manufacturing transformer, big and middle size motor, high or low electric switch, DC electric commutator and so on.

Copper extruding technology has many outstanding features compared with the traditional drawing technology:

1. Raw material can be pure copper or copper alloy

2. The production process doesn’t need annealing process, which helps to save more energy.

3. Simple production process. One mole can form the shape; It is convenient to change the mold.

4. With accurate dimensions and fine finish, our products possess very good mechanical and electric conduction ability.

5. The convenient production process is especially suitable for producing varieties of products in small quantity.

6. The equipment saves space for compact structure. What’s more, it costs not much to set and operate the equipment.

7. The equipment is characterized with less operators, energy-saving advantages, environment protection and less methodology consumption.

We can provide professional customized production lines, high-quality teams, and worry-free after-sales service. For more details, please visit "Contact Us".

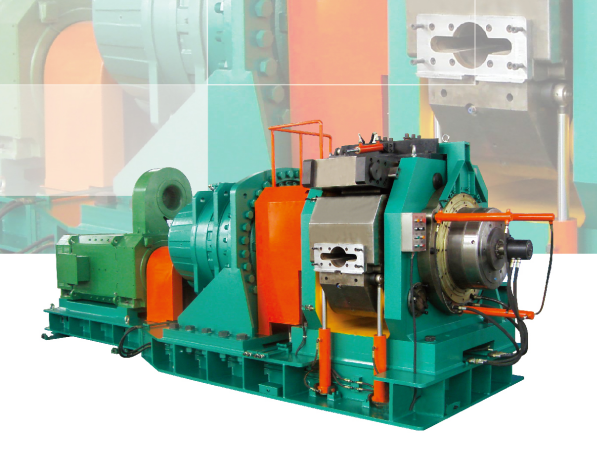

The copper/aluminum continuous extrusion machine from Shanghai Fortune Electric Co., Ltd

(copper/aluminum continuous extrusion mchine)

Equipment parameters of copper/aluminum continuous extrusion machine

Model FXE-300 FXE-350

FEX-400 FXE-550 FXE-650 FXE-300AL FXE-300HT Nominal diameter of extrusion wheel(mm)

300 350 400 550 650 300 Squeezing brass depends on the product situtation Power of main motor(KW)

90 180 250 450 650 110、132 Rotating speed of extruder

(rpm)4-12.5 4-12.5 4-12.5 3-8 3-8 4-22.5 Raw material

upward casting oxygen-free copper rod upward casting oxygen-free copper rod

upward casting oxygen-free copper rod

upward casting oxygen-free copper rod

upward casting oxygen-free copper rod

pure aluminum、aluminum alloy Diameter of wire rod

Φ.12.5±0.2 Φ13/Φ17

Φ20

Φ25

Φ30

Φ9.5/Φ12

Max. Width of the product(mm)

50 copper strip 100、copper rod Φ45

copper strip 170、copper rod Φ80

copper strip 260、copper rod Φ120

copper strip 350、copper rod Φ140

flat wire、flat tube width 32,round tube Φ5-20,wall thinckness:round tube 0.4-2 flat tube 0.3-1.5

Sectional area of the product(mm2)

6-300 80-1000 200-1600 300-4500 300-5500 180 Width-thickness ration of the product

≤15:1 ≤15:1

≤15:1

≤15:1

≤15:1

0 Average productivity(kg/h)

450 700 1200 1800 2500

Flash rate(%)

1-3 2-3 1-3 ≤5

≤5

Floor area 30*8*4cm 30*8*4cm

30*8*4cm

30*8*4cm

30*8*4cm

37*8*4cm

Products

- Horizontal Continuous Casting Machine

- CCR Line

- Upwards Continuous Casting Machine

- Semi-continuous Casting Machine

- Surface Milling Machine

- Rolling Mill

- Extrusion Machine

- Continuous Casting Dedusting Equipment

- Heat Treatment Furnace

- Air conditioning pipe project

- Continuous punching machine

- Other Related Devices

Contact us

|

Add.: No.519 Qifan Rd., Pudong District, Shanghai 201208, China

Mobile: +86-18017050010(Miss Zhang)

Mobile: +86-18918154455 (Ms. Alicia)

Whatsapp:+86-18918154455

Copper/Aluminum Continuous Extrusion Machine

Related Products